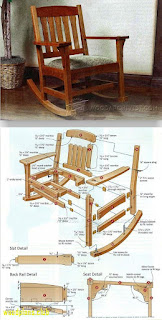

Crafting Modern Rocking Chairs: A Comprehensive DIY Guide

This comprehensive guide details the construction of two distinct modern rocking chair designs, providing detailed step-by-step instructions for the discerning woodworker. Each design emphasizes clean lines and contemporary aesthetics, utilizing readily available materials and straightforward joinery techniques. While woodworking experience is beneficial, these projects are achievable for intermediate-level craftspeople with careful attention to detail and precision.

Design 1: The Minimalist Rocker

This design prioritizes simplicity and elegance, featuring a streamlined silhouette and minimal ornamentation. The primary materials are hardwood lumber (e.g., oak, maple, or walnut) and high-quality wood screws. The curved rockers are created using a jig and router, simplifying the shaping process significantly.

Materials List:

- Hardwood lumber (1" x 6" x 8') for seat and back supports: Approximately 2 boards

- Hardwood lumber (1" x 4" x 8') for legs and rocker supports: Approximately 4 boards

- Hardwood lumber (1" x 2" x 8') for stretchers: Approximately 2 boards

- Wood screws (2 1/2" and 1 1/4"): Assortment for various joining tasks

- Wood glue: High-quality wood adhesive

- Rocker template (printable): Downloadable from [insert link here â€" replace with a suitable link or description of template creation]

- Router with round-over bit: For shaping edges and rockers

- Jig for shaping rockers (optional): Simplifies the rocker creation process.

- Sandpaper (various grits): For smoothing surfaces

- Finishing supplies: Stain, sealant, or paint of your choice.

Step-by-Step Instructions:

- Cut the lumber to size: Using the provided plans (or your own design based on the minimalist aesthetic), precisely cut the lumber to the designated dimensions. Accurate measurements are crucial for a stable and aesthetically pleasing chair.

- Create the rocker templates: If not using a pre-made template, create the rocker templates by carefully drawing the curves onto a sturdy piece of material. The template will guide the router when shaping the rockers.

- Shape the rockers: Securely attach the rocker template to the lumber intended for the rockers. Use a router with a round-over bit to follow the template's curve, creating the desired rocker shape. A jig will significantly improve accuracy and ease this process.

- Assemble the legs and rocker supports: Using wood glue and screws, join the legs and rocker supports to create the chair's base. Ensure the joints are aligned perfectly for structural integrity.

- Attach the seat and back supports: Carefully attach the seat and back supports to the base, ensuring they are securely fastened and level. Use wood glue and screws for robust connections.

- Add stretchers: Attach the stretchers between the legs to enhance stability and prevent racking. Use mortise and tenon joints for a stronger, more aesthetically pleasing connection (optional, but recommended).

- Sand and finish: Thoroughly sand all surfaces, starting with coarser grits and progressing to finer grits for a smooth finish. Apply the chosen stain, sealant, or paint, following the manufacturer's instructions.

Design 2: The Sculptural Rocker

This design features a more dramatic, sculpted form with flowing curves and a higher degree of complexity. It requires a greater level of woodworking skill and potentially specialized tools, but the result is a strikingly modern and visually captivating rocking chair.

Materials List:

- Hardwood lumber (various dimensions): This design requires more intricate shaping and may necessitate different board thicknesses for specific components. A detailed cutting list will be provided in the accompanying plans (see note below).

- Wood screws (various sizes): Similar to Design 1, but a wider range of sizes may be needed.

- Wood glue: High-quality wood adhesive.

- Band saw or jigsaw: For intricate curves and shaping.

- Sanding tools (orbital sander, hand sanding blocks): Essential for smoothing intricate shapes.

- Router with various bits: For detailed shaping and edge detailing.

- Templates (printable): Detailed templates will be provided in the accompanying plans (see note below).

- Finishing supplies: Stain, sealant, or paint.

Note: Detailed cutting lists and printable templates for Design 2 are available for download from [insert link here â€" replace with a suitable link]. Due to the complexity of this design, referring to these supplementary materials is essential.

Step-by-Step Instructions:

- Cut the lumber to size: Based on the provided plans, carefully cut the lumber to the specified dimensions. Precise measurements are paramount for this intricate design.

- Shape the components: Using the band saw or jigsaw, cut out the complex curves of each component, following the provided templates. This step requires careful planning and execution.

- Refine the shapes: Use the router with appropriate bits to further refine the shapes and create smooth transitions between curves. Pay close attention to detail during this stage.

- Assemble the chair: Begin by assembling the rockers and legs, followed by the seat and back supports. Utilize wood glue and screws for strong joints. Consider using dowel joints or other reinforcing techniques for added strength in critical areas.

- Sand and finish: Thoroughly sand all surfaces using various grits of sandpaper. Pay special attention to areas with intricate curves. Apply the chosen finish to highlight the sculpted form.

- Optional: Add upholstery: This design may benefit from adding upholstery to the seat and back for enhanced comfort. Select upholstery fabric that complements the chair's style and finish.

Safety Precautions: Always wear appropriate safety glasses and hearing protection when operating power tools. Follow all manufacturer instructions for the safe use of woodworking equipment. Ensure proper ventilation when working with stains and sealants. Accurate planning and meticulous execution are crucial for success in these projects. Take your time, and enjoy the process of creating a unique and beautiful piece of furniture.